Pharmaceutical Validation: Ensuring Quality, Safety, and Regulatory Compliance

02 Dec, 2025

In the pharmaceutical world, the stakes are high. Patients rely on the medicines they take every day to be safe, effective, and consistent. Behind every successful batch of a drug is a process that has been carefully validated to ensure quality and compliance.

Pharmaceutical validation is not just a regulatory requirement; it is the backbone of trust between manufacturers, regulators, and patients. It ensures that processes, equipment, and systems reliably produce products that meet predefined standards for quality, safety, and efficacy.

What Is Pharmaceutical Validation? Think of pharmaceutical validation as a way of saying, “We know our process works, and we can prove it.”

It is the documented process that confirms manufacturing processes, equipment, and testing methods consistently deliver the desired results. Unlike quality control, which checks the final product, validation focuses on the process itself to ensure it is reliable from start to finish.

Key Points About Pharmaceutical Validation:

| Aspect | Description |

| Purpose | Ensure processes consistently produce products meeting quality standards |

| Scope | Equipment, processes, cleaning, analytical methods, and computer systems |

| Basis | Good Manufacturing Practices (GMP) and regulatory guidelines |

| Outcome | Documented proof of process reliability and reproducibility |

By validating processes, manufacturers reduce variability, minimize errors, and ultimately protect patient safety.

Why Pharmaceutical Validation Matters

1. Ensures Consistent Quality: A validated process guarantees that every batch of medicine meets the same high standards for purity, potency, and stability.

2. Protects Patient Safety: Validation controls potential risks, including contamination, improper potency, or instability.

3. Demonstrates Regulatory Compliance: Regulatory agencies like the FDA, EMA, and WHO require manufacturers to validate processes to comply with GMP standards.

4. Improves Efficiency and Reduces Costs: Validated processes reduce rework, unnecessary testing, and waste.

Benefits Summary Table:

| Benefit | How It Helps |

| Consistent Quality | Reduces batch-to-batch variation |

| Patient Safety | Minimizes risks of contamination or errors |

| Regulatory Compliance | Ensures audit readiness and avoids sanctions |

| Operational Efficiency | Reduces rework, waste, and production costs |

Types of Pharmaceutical Validation

Validation is not one-size-fits-all. It covers multiple aspects of manufacturing and testing.

| Type | Purpose |

| Equipment Qualification (IQ/OQ/PQ) | Ensures equipment is installed correctly, operates reliably, and performs as intended |

| Process Validation | Confirms that the manufacturing process consistently produces quality products |

| Cleaning Validation | Ensures cleaning procedures remove residues to prevent cross-contamination |

| Analytical Method Validation | Verifies testing methods are accurate, reliable, and reproducible |

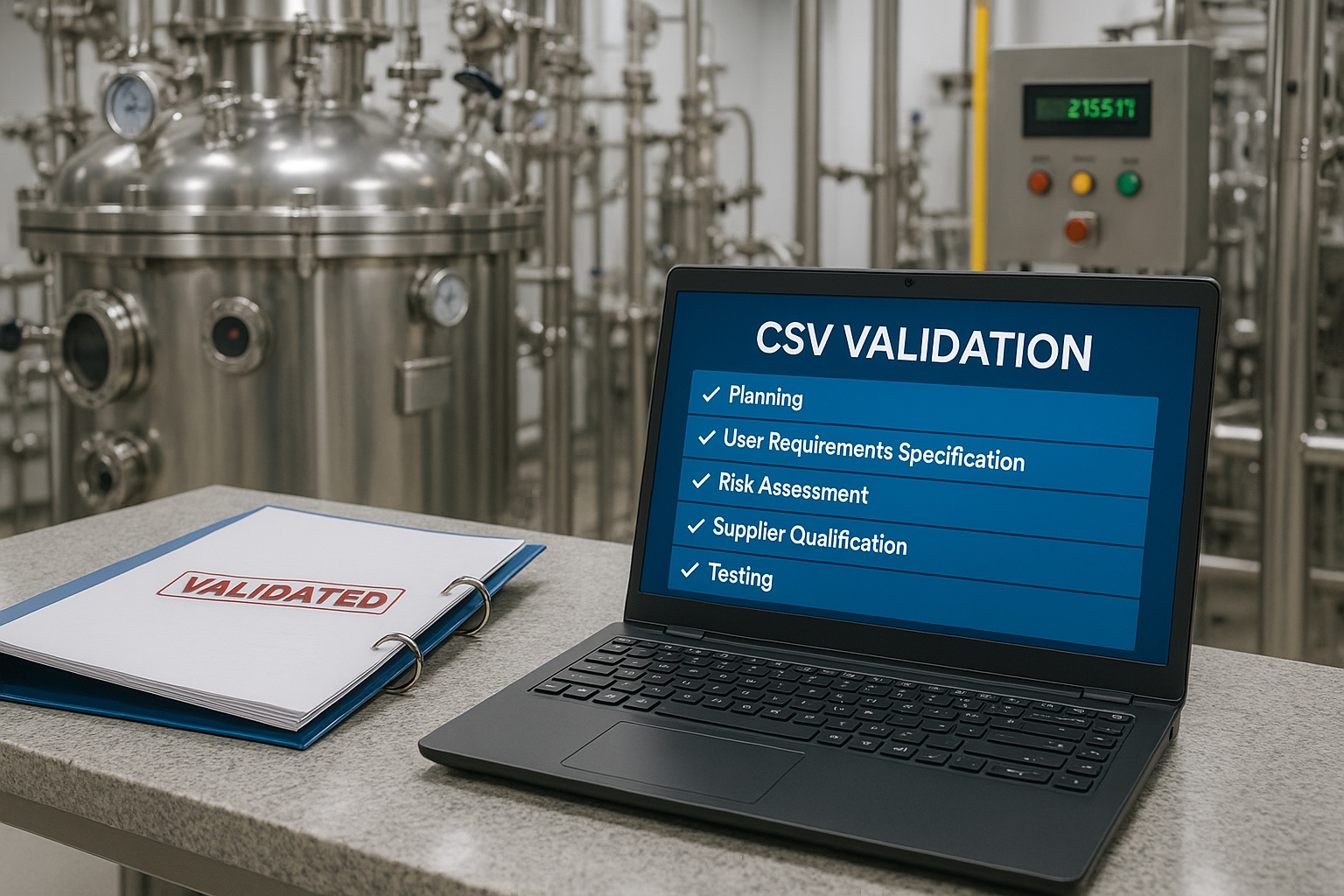

| Computer/System Validation | Confirms that software and automated systems function reliably and securely |

The Three Stages of Process Validation.

Validation is a journey, not a one-time task. The FDA and other agencies outline a three-stage lifecycle for process validation:

| Stage | Description | Key Activities |

| Stage 1: Process Design | Develop the process based on scientific understanding | Define Critical Quality Attributes (CQAs), identify Critical Process Parameters (CPPs), risk assessments, and establish control strategies |

| Stage 2: Process Qualification | Test the process under production conditions | Equipment qualification (IQ/OQ/PQ), trial batches, monitoring results, document reproducibility |

| Stage 3: Continued Process Verification | Ensure ongoing consistency | Continuous monitoring of process parameters, periodic reviews, corrective actions, and revalidation if needed |

A Validation Master Plan (VMP) guides this entire lifecycle, clearly outlining scope, responsibilities, timelines, and acceptance criteria.

Challenges in Pharmaceutical Validation

1. Complex Processes and Equipment – Modern manufacturing is intricate, requiring detailed validation for each step.

2. Documentation Management – Accurate and complete records are essential for compliance and audits.

3. Changing Regulations – Regulatory requirements evolve, requiring periodic reviews and updates.

4. Balancing Efficiency and Compliance – Upfront effort is significant, but it reduces long-term risk and cost.

Best Practices for Effective Validation

| Best Practice | Key Tip |

| Comprehensive VMP | Plan the scope, responsibilities, timelines, and acceptance criteria upfront |

| Identify Critical Parameters | Focus on CQAs and CPPs, using risk assessments to prioritize validation efforts |

| Qualify Equipment and Systems | Ensure all equipment, cleaning procedures, and analytical methods are validated |

| Document Everything | Protocols, deviations, corrective actions, and reports must be thorough and accurate |

| Continuous Monitoring | Use Continued Process Verification to detect trends and maintain control |

| Embed Quality Culture | Promote proactive risk management and continuous improvement across teams |

Conclusion

Pharmaceutical validation is more than a regulatory checkbox; it is the foundation of trust. It guarantees that the medicines reaching patients are safe, effective, and consistently high quality.

A strong validation program reduces risks, improves efficiency, and ensures compliance with global regulatory standards. For pharmaceutical companies, investing in validation is investing in reputation, patient safety, and long-term success.

At helpwithvalidation.com, we believe that robust validation practices are essential for building quality medicines that patients can rely on batch after batch, dose after dose.